With sustainability certifications (green certifications), manufacturers can guarantee that people, work conditions, and the environment are respected.

How can you, with your purchase, make an impact on the environment and society?

It’s important starting by understanding what is the impact of green certifications on the environment.

Then, look for sustainable products, or Bluesign approved items on Outdooreer’s catalog!

30-second summary

– The leading sustainability certifications for outdoor equipment are B Corporation, Bluesign, Global Organic Textile Standard, OEKO-TEX, SA8000, and SWS – Sustainable Web Store) have an impact at different stages of the textile supply chain on the environment, workers, and customers.

– You can make an impact on the environment and society by purchasing products with sustainability certification labels.

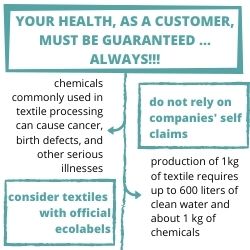

– Because your health, as a consumer, must be protected, sustainability companies’ self-claims cannot be trusted.

The textile industry leaves one of the largest footprints in the global environment. You may already know it, but it’s still a good reminder!

In this article, you can read about:

- The impact on the environment by sustainability certification

- The future of manufactures – green certifications

- Sustainability certification, why don’t rely on self claims

- Leading sustainability certifications ( B Corporation, Bluesign, Global Organic Textile Standard, OEKO-TEX, SA8000, and SWS – Sustainable Web Store)

- The supply chain of the textile industry

- Human rights abuses in the textile industry

- Which sustainability certifications have an impact on the environment?

- Which sustainability certifications have an impact on society?

Impact on the environment group by sustainability certifications

The impact of sustainability certifications (also commonly called a green label or green certifications) can have a massive impact on the environment.

Depending on the label, the prevention of the environment varies from land use to waste in the landfill.

With these information you can make an impact on the environment while purchasing a product!

| Sustainability certification | Environmental impact |

|---|---|

| B Corporation | – Land use – Pesticides – Preservatives – Water demand, pollution, and waste – Air pollution and dust emission – Chemicals and hazardous chemicals – Fiber waste – Noise pollution – Energy demand – Waste |

| Bluesign | – Chemicals and hazardous chemicals – Water demand, pollution, and waste – Air pollution and dust emission – Noise pollution – Fiber waste – Energy demand – Waste |

| Global Organic Textile Standard | – Land use – Pesticides – Preservatives – Water demand, pollution, and waste – Air pollution and dust emission – Fiber waste – Noise pollution – Chemicals and hazardous chemicals – Energy demand – Waste |

| OEKO-TEX | – Water demand, pollution, and waste – Air pollution and dust emission – Chemicals and hazardous chemicals – Fiber waste – Noise pollution – Energy demand – Waste |

| SWS Sustainable Web Store | – Energy demand – Water consumption and water pollution (micro-plastics) – Land pollution – Air pollution – Waste |

The future of manufactures – green certifications

Textile companies recognize that focusing only on profits has led to devastating effects on people, but also the destruction of natural resources, especially the world’s most vulnerable area.

The number of companies that consider among their core values environmental sustainability and environmental impact in production processes for their goods it’s increasing.

Increasingly, brands and retail chains are starting to realize the significance of social responsibility towards workers and customers.

This is a trend that has developed in recent years and will stay for many years to come.

Green certifications, why you shouldn’t rely on self claims

You shouldn’t rely on companies’ self claims.

Particularly when environmental issues, social problems, or consumer protection are involved.

Your health, as a consumer, must be protected. ALWAYS!

Especially considering that some kind of chemicals commonly used in textile processing can cause cancer, birth defects, and other serious illnesses.

Do you know that the production of 1kg of textile requires up to 600 liters of clean water and about 1 kg of chemicals, it’s about 10 millions of tons of chemicals a year.

Considering different ethical aspects, how chemicals are treated, are poured into rivers?

Are working conditions respected? What you have just bought, is really made of organic cotton or organic wool?

Look for labels of sustainability certifications. Most of them are widely recognized in major sales markets around the world.

Leading sustainability certifications

- B Corporation

- Bluesign

- Global Organic Textile Standard

- OEKO-TEX

- SA8000

- SWS – Sustainable Web Store

B Corporation

B Corporation is a company certification designed to ascertain equal weight to people, planet, and profit.

Certified B Corporations are accelerating a global culture shift to redefine success in business and build a more inclusive and sustainable economy.

What it guarantees

The B Impact Assessment evaluates how your company’s operations and business model impact workers, community, environment, and customers. From the supply chain and input materials to your charitable giving and employee benefits.

Holding the certification indicates the company’s environmental performance, employee relationships, diversity, involvement in the local community, and the impact a company’s product or service has on those it serves.

How it works

To become certified, businesses must achieve a minimum score across a range of areas, including environmental, social, and legal standards, as well as transparency and accountability requirements.

Bluesign

Bluesign is a standard for environmental health and safety in the manufacturing of textiles.

It’s is an independent chemical auditor that works with producers, manufacturers, and brands to reduce harmful chemicals in the textile industry and the ecological footprint.

What it guarantees

The Bluesign standard analyzes all input streams – from raw materials and chemical components to resources.

The auditing system excludes substances that are harmful to the environment and to health from the very beginning of the manufacturing process, instead of focusing on finished product testing.

To ensure environmentally friendly and safe production, all the steps in the manufacturing process are comprehensively monitored by independent bodies, as well as the highest standards concerning the use of resources, consumer protection, water, and air emissions as well as workplace safety.

Label

There are two possible markings on the products: Bluesign product and Bluesign approved fabric. A Bluesign product not only relates to the fabric used to make it, but also the buttons, strap buckles, zips and drawstrings.

Global Organic Textile Standard

Global Organic Textile Standard (GOTS) defines environmental criteria along the entire organic textiles supply chain, from harvesting of the raw materials, through environmentally and socially responsible manufacturing up to labeling in order to provide a credible assurance to the end consumer.

What it guarantees

Only textile products that contain a minimum of 70% organic fibers can become GOTS certified. All chemical inputs such as dyestuffs and auxiliaries used must meet certain environmental and toxicological criteria.

GOTS includes a wide range of strict criteria to guarantee that workers and environment won’t be harmed.

GOTS prohibits the use of the kind of chemicals commonly used in textile processing that can cause cancer, birth defects, and other serious illnesses. In order to protect the consumer, the manufacturing process can only use low-impact chemicals.

GOTS also includes stringent restrictions on wastewater treatment, and requires target goals and procedures to reduce water and energy consumption.

Also social criteria based on the key norms of the Internaltional Labour Organization must be met these include safe working conditions, no discrimination and no child labour.

OEKO-TEX

The Oeko-Tex Standard 100 is a globally uniform testing and certification system for textile raw materials, intermediate and end products at all stages of production.

What it guarantees

The independent certification system for the textile chain. This system make possible to comprehensively analyze the production plant sustainability.

The system optimize the plant existing production conditions in terms of using environmentally friendly technologies and products as well as assessing internal working condition and plants impact on the environment.

SA8000

SA8000 is an auditable certification standard that encourages organizations to develop, maintain, and apply socially acceptable practices in the workplace.

The SA8000 certificate is based on ILO standards and is applicable to factories, not products.

What it guarantees

The SA8000 Standard is based on internationally recognized standards of decent work, including the Universal Declaration of Human Rights, ILO conventions, and national laws. SA8000 applies a management-systems approach to social performance and emphasizes continual improvement—not checklist-style auditing.

SWS – Sustainable Web Store

Sustainable Web Store certification assesses the last link in the supply chain, the purchasing phase between retailer and consumer.

What it guarantees

The certification guarantees the web-store provides effective and quality information to customers to allow a correct and conscious purchase.

The sustainability aspect of the certification focuses on increasing the life of the item and decreasing the carbon footprint.

Read more about Sustainable Web Store certification.

The supply chain of the textile industry

The textile supply chain is long and complex.

It starts from the raw materials, and it ends up in the landfill, going through the production process and the customer use, creating a massive impact in the supply chain on the environment and people.

Environment

The impact of the textile industry on the environment at each stage of the textile supply chain, from raw materials and manufacturing processes to waste is massive.

It includes the carbon and water footprint, the use of hazardous chemical substances, wastewater quality, the disposal of used clothing, and recycling.

Raw materials

In the textile industry, raw materials are either natural (from nature) or petroleum oil-based. The raw material is processed into fibres.

Natural fibers

Natural fibres are usually farmed and can be plant-based such as cotton or animal-based such as wool.

Stages: Planting, cultivation, harvesting, ginning.

Environment damage: Land use, pesticides, preservatives, water demand

Semi-synthetic or synthetic fibers

Semi-synthetic means the fiber is man-made but based on natural raw materials such as bamboo and cellulose. Man-made fibers can be non-organic, meaning glass or metal, or organic meaning oil-based or wooden fibers.

Transforming oil to fibers is a chemical process and in fact, synthetic fibers can be dyed during this stage of the supply chain.

Stages: Polymerization, pumping, filtration.

Environmental damage: Hazardous chemicals, water pollution, air pollution.

Fabric manufacture

Yarn manufacture

The yarn manufacturing process transforms the raw cotton fiber into, first the cotton yarn, and later to a sheet of cloth. Then, they are shipped to garment manufacturing facilities.

Stages: Purification, cleaning, spinning, twisting, weaving, knitting

Environmental damage: Chemicals, fiber waste, noise pollution, dust emission,

Textile finishing

When the cotton is prepped and dyed, it’s ready for the last steps of the finishing process.

In this stage, a number of mechanical and chemical techniques are applied to get the desired texture and properties out of the cloth

Stages: Purification, cleaning, dyeing, printing

Environmental damage: Water demand, wastewater pollution, hazardous chemicals, energy demand.

Garment manufacture

The final product finally takes shape, for example, it turns into your cotton t-shirt.

Stages: Cutting, assembling, finishing, pressing, packaging

Environmental damage: energy demand, waste, chemicals

Warehouse

Once the shirt leaves the doors of the garment factory, the shirt will head to a distribution warehouse or directly to the retail store.

Stages: Distribution system

Environmental damage: Emission, solid waste

Consumer use

Consumer use, because of washing, drying, and ironing has approximately the same environmental impact on the production process.

Stages: Purchase, consumer use, washing, drying, ironing.

Environmental damage: Energy demand, water consumption, water pollution (micro-plastics).

Waste

When the life of a garment reaches the end, there are five possibilities: incinerated in waste-to-energy plants, landfills, sent to third-world countries before ending up in landfills, re-sold / re-used or recycle.

Unfortunately, recycling garments upstream is a complicated and too expensive process.

Stages: end of life, distribution on third world countries.

Environmental damage: Water, land and air pollution.

Human rights abuses in the textile industry

In our globalized economy, businesses across all sectors increasingly source all manners of goods and services from complex chains of suppliers that often span multiple countries with radically different legal, regulatory, and human rights practices.

Individual companies’ global supply chains often involve large numbers of suppliers or subcontractors, including some who are part of the informal sector.

The people most affected by human rights abuses in a company’s supply chain often belong to groups who have no real opportunities to call attention to these problems themselves or secure a remedy, such as women workers, migrant workers, child laborers, or residents of rural or poor urban areas.

These are the most common human rights abuses in a company’s supply chain:

- Child labor

- Discrimination

- Denial of paid maternity leave

- Denial or low remuneration

- Forced overtime

- Forced or compulsory labor

- Pregnancy-based discrimination

- Harmful environments

Sustainability certifications impact

The sustainability certifications and standards have an effect on different areas of the textile supply chain generating an impact from the environment to society.

Impact of sustainability certifications on supply chain

| Textile supply chain | Stage | Environmental damage | Sustainability label |

|---|---|---|---|

| Raw materials – natural fibers | – Planting – Cultivation – Harvesting – Ginning | – Land use – Pesticides – Preservatives – Water demand | – B Corporation – GOTS |

| Raw materials – semi-synthetic or synthetic fibers | – Polymerization – Pumping – Filtration | – Hazardous chemicals – Water pollution – Air pollution | – Bluesign – B Corporation – GOTS – OEKO-TEX |

| Yarn manufacture | – Purification – Cleaning – Spinning – Twisting – Weaving – Knitting | – Chemicals – Fiber waste – Noise pollution – Dust emission | – Bluesign – B Corporation – GOTS – OEKO-TEX |

| Textile finishing | – Purification – Cleaning – Dyeing – Printing | – Water demand – Wastewater pollution – Hazardous chemicals – Energy demand | – Bluesign – B Corporation – GOTS – OEKO-TEX |

| Garment manufacture | – Cutting – Assembling – Finishing – Pressing – Packaging | – Energy demand – Waste – Chemicals | – Bluesign – B Corporation – GOTS – OEKO-TEX |

| Warehouse | – Distribution system | – Air pollution – Solid waste | – B Corporation |

| Consumer use | – Purchase – Consumer use – Washing – Drying – Ironing | – Energy demand – Water consumption – Water pollution (micro-plastics) | – SWS Sustainable Web Store |

| Waste | – End of life – Distribution on third world countries. | – Water pollution – Land pollution – Air pollution | – SWS Sustainable Web Store |

Impact of sustainability certifications on society

Some green certifications have an impact on society, rising and set the standards in the working environment.

| Impact on human rights | Sustainability certification |

|---|---|

| – Extremely low salaries – Experience forced overtime – Pregnancy-based discrimination – Denial of paid maternity leave – Child labor – Forced or compulsory labor – Harmful environments | – B Corporation – GOTS – SA8000 |